Basement Finish!

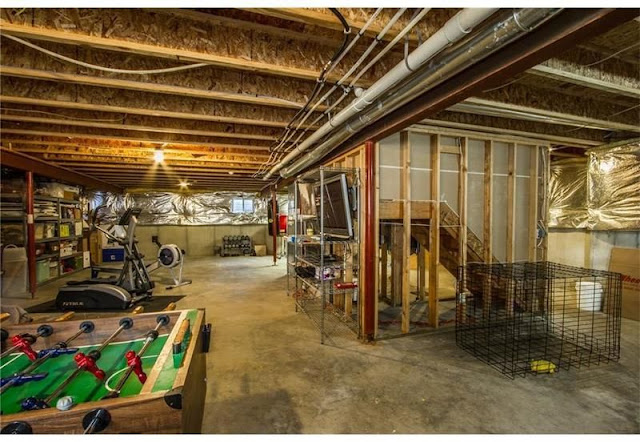

When we were looking at houses last winter, one of the major things that caught our eye about our new house was the unfinished basement. It was a great house in a great neighborhood, and when we saw the picture on the listing of the unfinished basement (above), we saw a ton of potential. The project was equal parts amazing and fulfilling and frustrating and overwhelming. However, after about 9 months and a lot of late nights, we finally turned the basement into an awesome space for our family.

As we walk through it now, it's crazy to think that at the beginning it was just an idea. Of course, there's still more to do - we still have to decorate and buy furniture and put in a backsplash - but isn't that the nature of any big project like this? Regardless, I couldn't be more proud of the way it turned out, and I'm excited to share some before and after pictures. Enjoy the photo tour below below!

(Note that there's a lot of detail below because many have asked me for it. If the details don't interest you, skip to the last few pictures and the final walk through at the bottom :)

|

I also took it a step farther and created renderings for the basement - this helped me visualize the space and allowed me to move furniture around and see how the spacing would end up. It was very helpful. All of this is also done in sketch-up.

After the design was complete and my permits were pulled, I ordered a truckload of wood and started framing. Framing was one of the more rewarding parts of the project because we could see the space start to take shape. I learned how to use a whole host of tools that I'd never heard of, like ramset and a plumb bob. I also quickly learned that the engineering definition of 90 degrees and the framing definition of "90 degrees" are not the same. :)

Here is a shot of what will eventually be the living room area. Also pictured: the boys "helping". They were great helpers throughout this whole project, and really enjoyed helping me put things together.

After framing was electrical, plumbing, fire blocking, and HVAC. The first thing I did is farm out a couple small tasks - I had an electrician run a 60 amp sub panel from my garage to my basement so I would have all the basement power contained in a single panel that would be easy to get to. I had a plumber install my sewage ejector, and I also had an HVAC company run four vents and one return line to heat and cool the basement. I farmed those out not because I couldn't do them, but because they were really very reasonable to have done. Other than that, I did everything in the rough in myself.

I ran nine electrical circuits in total, including several dedicated lines for things like a fridge, dishwasher, a dedicated bathroom circuit, etc. I ran 15A lighting circuits and 20A outlet circuits, and did all the wiring myself, in the panel, and to each outlet and light. Lights are all 6" can lights other than a select few places (like a vanity light in the bathroom).

For plumbing, the basement was already roughed in for a full bathroom, meaning the drain lines were put in before the concrete was poured. I tapped into those for the toilet, vanity, and shower, and tied into the vent stack so everything was properly vented. I also ran a drain line to the bar sink, which ended up being about a 25' line that had to turn several corners, and was one of the more complex things I did. I ran pex lines for all the water supply lines to the toilet, shower, vanity, and bar sink, and I put water shutoff valves on both hot and cold in the basement, so I could shut off the water down there and work without killing water to the entire house.

Here's the update video, which I took right before my first of three inspections. (The Rough Inspection). I passed the rough inspection with conditions (some very minor things I had to fix after the fact).

After roughing everything in, it was time for insulation. The walls were already half-insulated by the builder, but the town of Zionsville didn't count that, because that would make too much sense. So, I had to re-insulate all of the exterior walls. In addition, I used insulation for soundproofing in quite a few areas, which really ended up helping a lot. I put R-13 bats in the interior walls of the office and bedroom, and put R-30 bats all of the ceiling cavities to dampen some sound coming from upstairs.

Insulation was a hot, messy, dirty, irritating job. I had to wear safety glasses, gloves, a mask, a hat, and long sleeves, and my skin still itched like crazy. I'm sure it was necessary, but this was definitely a job I was ready to be done with. Below shows the angled wall for the bedroom, with insulation on the interior and exterior walls.

After insulation was the second inspection (Energy Inspection). This inspection was basically a pass/fail - either you did insulation (with the right R-value) or you didn't - the inspector was in my house for about 4 minutes.

Once I passed that, it was time for drywall! My original plan was to do drywall myself, but when I got there, I just didn't have it in me to drywall 1400 sq ft of basement, so I hired that out. Indy Painters does a great job, and has now done work for us in two houses. They hung the sheet rock in literally eight hours. IT took them a grand total of five days to go from bare studs to completely finished, including ceiling texture and priming the walls. It was truly incredible. Expensive, but totally worth it.

This is the drywall going up in the main living area. Below that is a shot of what will become the bar area.

Heres a quick video that shows what the basement looked like right after they hung the drywall - this was an exciting day!!

Once drywall was up, there was a LOT of work to do. Doors and trim, bathroom shower walls, order cabinets/appliances/granite for the bar area, schedule carpet, and on and on and on.

Trimming the basement was easier than I expected. The doors went in very easily, and once I got the hang of it I could hang a door and trim it out in about 45 minutes. The trim along the floors was slightly more challenging, as it required very precise cuts and a lot of trial and error. I also had to learn how to use a coping saw, which was tricky. Here's a shot of the doors and trim going in. This picture was taken standing in the bedroom - closet door on right and bedroom door on left (which opens to the living room area). Below that is a shot of the shower walls being installed. We used an Onyx shower from Lowes and are incredibly happy with it. It was very easy to install, and their customer service was absolutely fantastic. (I dropped and broke one of the shower panels and they totally took care of me.) The shower walls are panels made to look like subway tile.

Once we finished trim, it was time for painting. Indy Painters came back for me and made quick work of painting the colors that Kara picked, and they made quick work of that also.

Here's an update video that I posted after painting was done.

After painting it was time for flooring and finishes. I layed vinyl click-together planks in the bathroom, office, and bar area, and we are really happy with the result. (Definitely recommend Smartcore flooring from Lowes). In addition, we ordered and installed Kraftmaid cabinets in the bar area. Here's a shot of the bar area that shows the flooring as well as the cabinets going in.

After flooring went in, we were really in the home stretch. Carpet was installed, and all the finishes went in. (Outlet covers, light bulbs and rings, hvac register covers, closet shelving, door handles and door stops, etc). The appliances got delivered for the bar, and the granite got installed. I installed the bathroom vanity, the toilet, and did all the under-sink plumbing for the bathroom and the bar. I also installed, painted, and stained the banister for the stairs. After touching up paint, it was time to move some furniture in and celebrate.

Below are a few shots of the finished space, and a video walk through I did about a week ago.

So there you have it. This project is bigger than anything I've ever attempted by an order of magnitude, and I think for a newbie who admittedly knew nothing about most of this stuff when I started, I'm thrilled with the way it turned out. I'd be remiss if I didn't thank a handful of people:

- Kara - for all the help and support and ideas and help upstairs so I could bury myself downstairs.

- Friends and family, who helped by showing up when I asked, chipping in whenever they could, giving me an extra set of hands in the basement, or upstairs so I could go into the basement.

- Jon McCarty, for letting me borrow a ton of tools that I needed, which saved me a heck of a lot of money.

- Eddie Case at BasementFinishingVideos.com I cannot tell you how helpful these videos have been. They are fantastic - best $100 I've ever spent.

- The Whitestown Lowe's. That place became my second home, and there are some guys in there that made a huge impact in my ability to get this project done. Mike (plumbing), Allan (millwork), and Paul (cabinets) are just a few of the guys who I went to over and over and over to ask really, really dumb questions. It got to the point where Lowe's employees were asking how my boys were doing, and questioning where I was if they didn't see me for a couple of days. The people at that Lowe's are really fantastic. Everything you see in this basement was obtained at that Lowes, and I do mean EVERYTHING.

- Most of all, I want to thank my Dad, who taught me how to turn a wrench, swing a hammer, and take things apart. When I started this project, the first thing you said was "That sounds like a lot of work Dave but I know you can do it." I wish I could show you the finished product - I know you'd be proud. I miss you Dad.

Hope you enjoyed the post! If you have any questions or I can help you tackle a project on your own, I'd love to help! I've got the DIY itch!!!

Cheers.

Looks Amazing....so proud of you....Beautiful home for your beautiful family! Highly Impressed

ReplyDelete